An exhaust system shop specializing in turbo and header installs is key for top-tier vehicle performance upgrades. These installations, requiring knowledge of vehicle dynamics and safety standards, boost engine power through forced air intake and optimized exhaust flow. Shops provide critical expertise, tools, and resources for precise, manufacturer-spec modifications, integrating upgrades with other systems for optimal performance, reliability, and client satisfaction among automotive enthusiasts. To ensure seamless operations, focus on staff training, regular workshops, clean workspaces, and open communication.

“In today’s performance-oriented automotive landscape, exhaust system shops play a pivotal role in enhancing engine power through turbo and header installations. This article delves into the intricacies of these complex modifications, highlighting the expertise required by exhaust system shops. We explore how these professionals navigate the challenges, ensuring efficient and seamless installations. From understanding component interactions to implementing best practices, exhaust system shops are the backbone of successful turbo and header upgrades.”

- Understanding Turbo and Header Installs: A Comprehensive Overview

- The Role of Exhaust System Shops in Efficient Turbo and Header Installation

- Best Practices and Considerations for Seamless Shop Operations during Turbo and Header Installs

Understanding Turbo and Header Installs: A Comprehensive Overview

Understanding Turbo and Header Installs is essential for any exhaust system shop aiming to offer top-tier services. These upgrades are core to enhancing vehicle performance, especially in high-performance cars equipped with turbocharged engines. A turbocharger, often referred to as a ‘turbo’, forces extra air into an engine’s combustion chamber, boosting power output. This process requires careful installation to ensure optimal efficiency and safety.

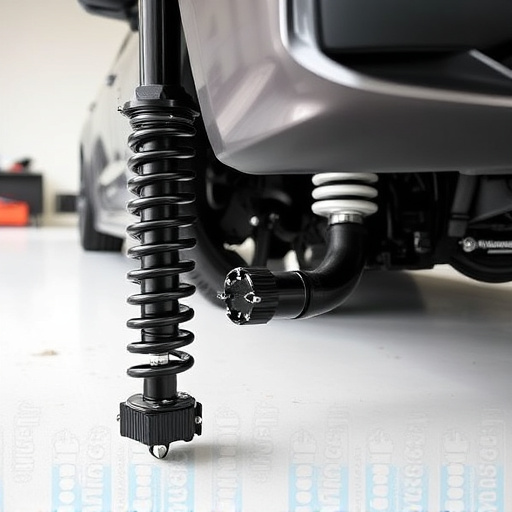

Header installs play a crucial role in this equation. Exhaust headers are components of the exhaust system that collect and direct exhaust gases from multiple cylinders. When installed with a turbocharger, they can significantly improve flow, reducing backpressure and enhancing engine performance. For exhaust system shops, mastering these installations involves understanding vehicle dynamics, utilizing specialized tools, and ensuring compliance with safety standards, all while catering to clients’ desired performance upgrades, such as those achieved through suspension kits or other performance exhaust components.

The Role of Exhaust System Shops in Efficient Turbo and Header Installation

Exhaust system shops play a pivotal role in facilitating efficient turbo and header installations for various vehicles. These specialized facilities are equipped with the necessary tools, expertise, and resources to handle complex modifications seamlessly. Skilled technicians at such shops ensure that every component, from exhaust tips to intricate intake systems, is meticulously aligned and installed according to manufacturer specifications.

Moreover, they offer a holistic approach by considering not just the turbo and headers but also their interaction with other critical vehicle systems, including suspension components. This comprehensive perspective guarantees optimal performance and reliability, ensuring vehicles not only run efficiently but also safely on the road. Their expertise in exhaust system modifications is invaluable, especially for enthusiasts seeking to enhance their vehicles’ capabilities.

Best Practices and Considerations for Seamless Shop Operations during Turbo and Header Installs

When conducting turbo and header installs at an exhaust system shop, maintaining seamless operations requires careful planning and adherence to best practices. First, ensuring proper training for technicians is paramount. Given the intricate nature of these installations, which often involve advanced components like turbos and custom headers, only well-versed staff should handle them. Regular workshops and certification programs can keep teams up-to-date with industry standards and innovations in exhaust systems.

Additionally, maintaining a clean and organized workspace significantly boosts efficiency. Proper storage for brake components, such as rotors, and easy access to tools and parts streamline the installation process. This reduces downtime and potential errors, ensuring quick turnaround times without sacrificing quality. Effective communication among staff is another critical factor, fostering a collaborative environment that enhances problem-solving capabilities during complex jobs like turbo and header installs.

Exhaust system shops play a pivotal role in facilitating efficient turbo and header installations, ensuring optimal vehicle performance. By adopting best practices outlined in this article, these shops can streamline operations, deliver high-quality work, and cater to the growing demand for turbo and header upgrades. Choosing the right shop for your vehicle’s needs is key, as it directly impacts the overall driving experience.