Exhaust system shops address noise and vibration issues by identifying faulty components, offering solutions from replacements to custom designs, and prioritizing driver comfort and safety standards. They employ sound insulation techniques with materials like fiberglass and acoustic foam, along with sealed doors and insulated windows, to maintain a peaceful environment. Best practices for vibration control include specialized mounting, suspension kits, high-quality tips, regular maintenance, and alignment, contributing to quieter rides and enhanced service quality.

In the bustling world of auto repair, exhaust system shops face a unique challenge: managing noise and vibration from exhaust components. This article delves into the intricate details of how these shops tackle these issues. We explore the primary sources of exhaust noise and vibration, dissect effective sound insulation strategies, and uncover best practices for mitigating vibrations within exhaust systems. By understanding these approaches, you’ll gain insights into enhancing workplace environments and customer satisfaction in exhaust system shops.

- Understanding Exhaust Noise and Vibration Sources

- Strategies for Effective Sound Insulation in Shops

- Best Practices for Mitigating Vibration in Exhaust Systems

Understanding Exhaust Noise and Vibration Sources

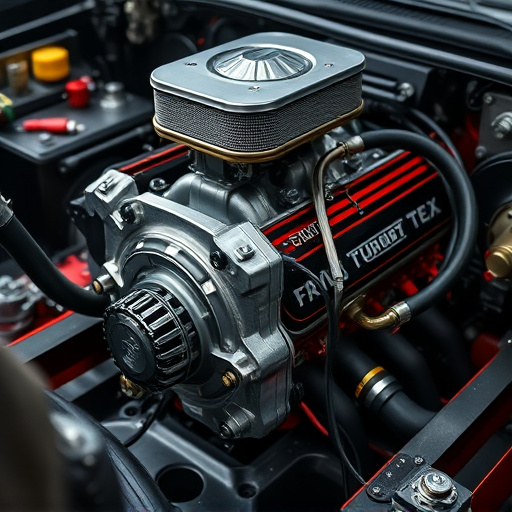

Exhaust system shops are tasked with addressing noise and vibration issues stemming from various components within a vehicle’s exhaust system. To effectively mitigate these problems, understanding the sources of exhaust noise and vibration is paramount. Common culprits include poorly designed or damaged mufflers, resonators, and exhaust tips, which can amplify sound waves and cause unwanted vibrations. Even the air intake systems, while not directly part of the exhaust system, can contribute to overall vehicle noise levels due to their interaction with engine operation.

Within an exhaust system shop, professionals employ specialized tools and techniques to diagnose these issues, such as vibration analyzers and sound level meters. Once identified, solutions range from simple replacements like switching out worn exhaust tips or cat back exhaust systems to more complex modifications involving custom-built mufflers and resonators tailored to specific vehicle needs. The goal is always to achieve a harmonious balance between engine performance and noise/vibration control, ensuring both the safety and comfort of drivers and surrounding communities.

Strategies for Effective Sound Insulation in Shops

Effective sound insulation is paramount for exhaust system shops to ensure a peaceful working environment and meet noise regulation standards. Strategies include employing dense, sound-absorbing materials like fiberglass matting, acoustic foam panels, and specialized sound barriers designed to dampen low-frequency noises common in automotive settings. Strategically placing these materials around work areas, equipment, and walls can significantly reduce the reverberation of loud sounds, minimizing exposure for employees.

Additionally, incorporating sealed doors, well-insulated windows, and sound-dampening flooring contributes to a quieter interior. For specialized tasks involving high-decibel processes like exhaust system repairs or welding, employing temporary noise barriers or ear protection for staff further enhances the overall acoustic comfort of the shop, fostering a safer and more productive atmosphere without compromising on the quality of services offered, such as those related to brake pad replacement, performance air filters installation, and vehicle performance tuning.

Best Practices for Mitigating Vibration in Exhaust Systems

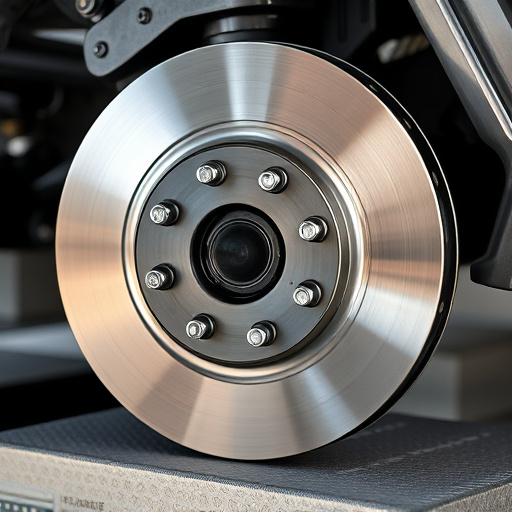

Exhaust system shops employ several best practices to mitigate vibration in exhaust systems. One effective method is using specialized mounting brackets and hangers designed to absorb excess vibrations, preventing them from propagating throughout the vehicle. Additionally, installing suspension kits can significantly reduce vibrations by providing a more stable base for the exhaust system components.

Another crucial step involves selecting high-quality exhaust tips that are engineered for reduced vibration. Performance air filters can also play a role in minimizing noise and vibration levels by ensuring smooth airflow, thereby decreasing turbulence which contributes to unwanted sounds. Regular maintenance checks and proper alignment of exhaust systems further contribute to maintaining optimal performance and minimizing vibrations.

Exhaust system shops play a vital role in addressing noise and vibration concerns, ensuring a peaceful environment for both workers and neighboring communities. By understanding the sources of exhaust noise and vibration, implementing effective sound insulation strategies, and adopting best practices for vibration mitigation, these shops can significantly reduce their impact. This not only enhances the overall work experience but also contributes to a quieter, more harmonious neighborhood. When exhaust system shops prioritize these measures, they demonstrate their commitment to both environmental responsibility and community well-being.